what is the difference between rockwell and brinell hardness test|brinell vs rockwell chart : distribute Brinell test is better than the Rockwell hardness test because it can measure the hardness of though material which is not measurable by another test like Rockwell. Brinell test . WEB26 de set. de 2023 · Ninguém acertou as seis dezenas sorteadas hoje no concurso 2637 da Mega-Sena, que teve prêmio estimado de R$ 5,2 milhões. Veja as dezenas, as .

{plog:ftitle_list}

Resultado da 3 de fev. de 2020 · Fabrini Bevilaqua Costa (SP) Aos 38 anos de idade, o assistente ingressou em 2005 na SENAF. Pertencente da Federação .

What is The Difference Between The Brinell and Rockwell Hardness Tests? While the two tests have similarities, there are several important differences. Both test methods are suitable for the testing of soft and medium hard materials such .Difference between, Brinell,Rockwell and Vickers Hardness Test What is Hardness? Hardness is the property of a material that enables it to resist plastic.Brinell’s hardness is a dimensionless size. In comparison with other hardness testing methods, Brinell’s ball leaves the deepest and largest print, and thus functionally and/or aesthetically . Brinell test is better than the Rockwell hardness test because it can measure the hardness of though material which is not measurable by another test like Rockwell. Brinell test .

The Rockwell test is better suited for materials with uniform hardness. Precision : The Brinell test tends to provide a more accurate measurement, especially for softer materials. The Rockwell test is faster but .

What is the difference between Brinell hardness and Rockwell hardness tests? The main differences between Brinell hardness and Rockwell hardness tests are in the shape of the indenter used, the load applied, the duration of load .

Have you ever wondered about the difference between Rockwell and Brinell hardness scales? In this article, we’ll dive into the world of material hardness testing, exploring the key distinctions between these two widely .

The difference between the two lies in the different heads of the hardness testers, with the Brinell hardness tester using a steel ball and the Rockwell hardness tester using a diamond. HV is suitable for microscopic .The Rockwell hardness test uses a hardened steel ball of a specific size that is pressed Into the material under a specified load. . Main Differences Between Brinell and Rockwell Hardness. The size of the indenter used in the Brinell .

Answer: BRINELL HARDNESS TEST: -BRINELL hardness test is the first test of hardeness test that invented. -It involves a carbide ball indenter that touches on the surface of the material that hardness has to be measured. -It is .View the full answer The method for conducting a Brinell hardness test is defined fully in ASTM E10. In general, to conduct the test, a certified Brinell indenter is pressed against a metal under a predetermined load for a predetermined .

Difference between, Brinell,Rockwell and Vickers Hardness Test What is Hardness? Hardness is the property of a material that enables it to resist plastic

Knowing the best-suited hardness test of the three, Rockwell, Brinell, and Vickers, for your hardness test will require that you understand the determining criteria for employing any hardness test. This article aims to distinguish these methods and help you find the most suitable one for your testing situation. Among the various hardness testing methods, the Brinell and Rockwell tests are two of the most commonly used techniques. In this article, we will compare these two methods, highlighting their differences and applications. Brinell Hardness Test. The Brinell hardness test is named after its inventor, Johan August Brinell. It measures the hardness . What is Brinell Hardness Test? The Brinell hardness test is the method measuring hardness through measuring the diameter of the indentation left by an indenter or other materials of a specified diameter, under a certain load into the surface. The Rockwell method is the most commonly used and versatile hardness test.

The Brinell hardness test is named after its inventor, Johan August Brinell. It involves applying a constant load or force to a spherical indenter made of hardened steel or carbide onto the surface of the material being tested. . The difference between HBS and HBW is the indenter. . The Rockwell hardness test is based on the indentation . The Rockwell test is the less destructive alternative to the Brinell test because it uses a smaller indenter. It is the easiest and least expensive hardness test to administer because it requires very little material prep. Unlike the Brinell Hardness Test, the Rockwell Hardness Test can also be used on many kinds of hardened materials.Brinell hardness test: - Uses a spherical indenter to create an indentation on the surface of the material being tested. - The diameter of the indentation is measured and used to calculate the Brinell hardness number. - Typically used for softer .

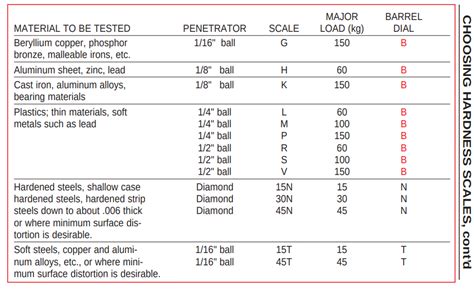

The Vickers test was time consuming, Brinell indents were too big for his parts and the Scleroscope was difficult to use, especially on his small parts. . The choice is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1⁄16, 1 .Main difference between Rockwell and Brinell hardness tester is principle of hardness testing. This difference in principle of Brinell and Rockwell hardness testing causes other differences like different indenter, load etc. . In Brinell hardness test hard ball indenter is pressed under load on surface of material. It is there for set dwell .Brinell hardness test: - Uses a spherical indenter to create an indentation on the surface of the material being tested. - The diameter of the indentation is measured and used to calculate the Brinell hardness number. - Typically used for softer .A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N. Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .

Because hardness varies between metals and even within the same metal group, hardness measurement methods such as Brinell and Rockwell hardness were developed to provide a common understanding of .Hardness tests of metals are essential to manufacture reliable big machines and automobiles. The hardness test should be first selected according to the needs of the material. You can find answers to questions about the Brinell and Rockwell in the article, as we have clarified the difference between the two tests.With its wide range of tests and commitment to top-notch practices, Infinita Lab is ready to support this need, driving innovation and ensuring quality in a variety of fields. Also learn about differences in Rockwell, Brinell, and Vickers metal hardness test. Video 01: Hardness testing (Brinell, Vickers and Rockwell test method) Abstract. There exist various types of experimental measurement of hardness, yet a unified understanding of various hardness measurements lacks. Here, by testing the hardness of a wide range of materials, we show that Rockwell and Brinell hardness tests, the two most used hardness measurements, are closely related. The experimental measurements agree .

What is The Difference Between The Brinell and Rockwell Hardness Tests? While the two tests have similarities, there are several important differences. Both test methods are suitable for the testing of soft and medium hard materials such as aluminum, Cu alloys, and soft steel. The Rockwell test is a quick and easy way to measure the hardness of a material. It involves applying a fixed load on a material using an indenter, which can be a diamond cone or a steel ball.

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.We would like to show you a description here but the site won’t allow us.A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale . A Rockwell hardness test and a Rockwell hardness scale are used to accomplishing this. ASTM E18 specifies the specific procedure. Rockwell hardness tests, like Brinell hardness tests, use an indenter of a given size applied with a predetermined force for a certain period of time. . What is the Difference between Rockwell and Brinell Tests .

Rockwell to Brinell conversion chart (Brinell, Rockwell A,B,C) Struers hardness conversion table (Vickers, Brinell, Rockwell B,C,D) This page was last edited on 18 December 2023, at 21:15 (UTC). Text is available under the Creative Commons Attribution-ShareAlike 4.0 .However, the Brinell hardness test requires an optical instrument like a microscope to determine the indentation on the material caused by the ball indenter. Related Article: What are the Advantages and Disadvantages of the Brinell Method III. What is the Difference between Rockwell and Brinell? Various features differentiate Rockwell and .

lego star wars at te drop test

WEBSomente na Abelvolks Store você encontra toda linha de Cordões Oficiais Abelvolks com os melhores preços! Quem Somos; Meus Pedidos; Fale Conosco; Atendimento 6299 972-9966 6299 972-9966 . ABELVOLKS COMERCIO E SERVICOS LTDA - CNPJ: 00.129.393/0001-38. Loja Virtual criada por DLoja Virtual.

what is the difference between rockwell and brinell hardness test|brinell vs rockwell chart